HOT AIR IMPINGEMENT METHOD (HVHAI )

- Low pressure air 2-5 psi

- Distribution through stainless steel pipes

- Low inertia electric heater

- Manifold distribution system

- Flow control balancing valve

- Air jets directed at bond lines

- Application of heat

- Controlled temp. – 200-375F -93-190C

- Confined positioning – to the adhesive area

- Zoned heat control with thermocouple feedback

- Removal of heat before release of assembly

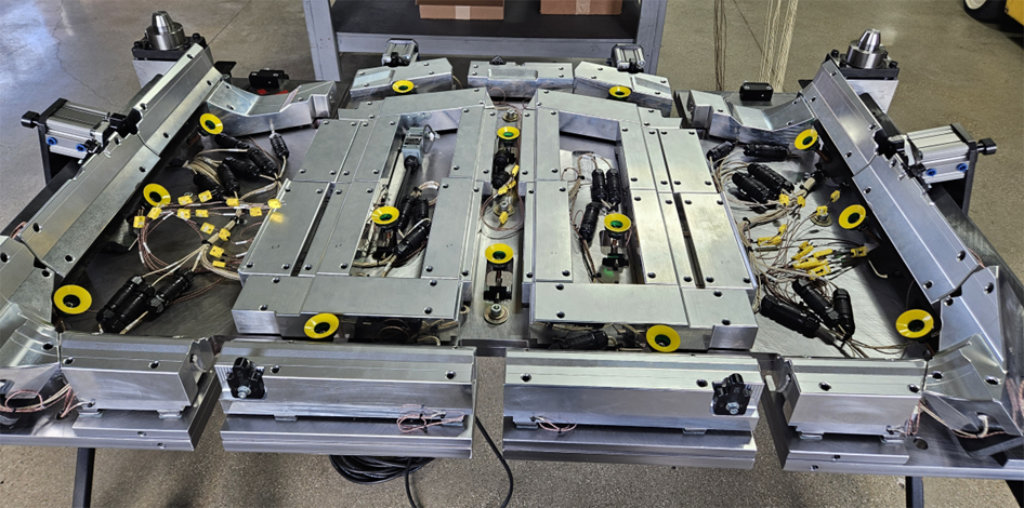

- Air jets encapsulated in support fixtures

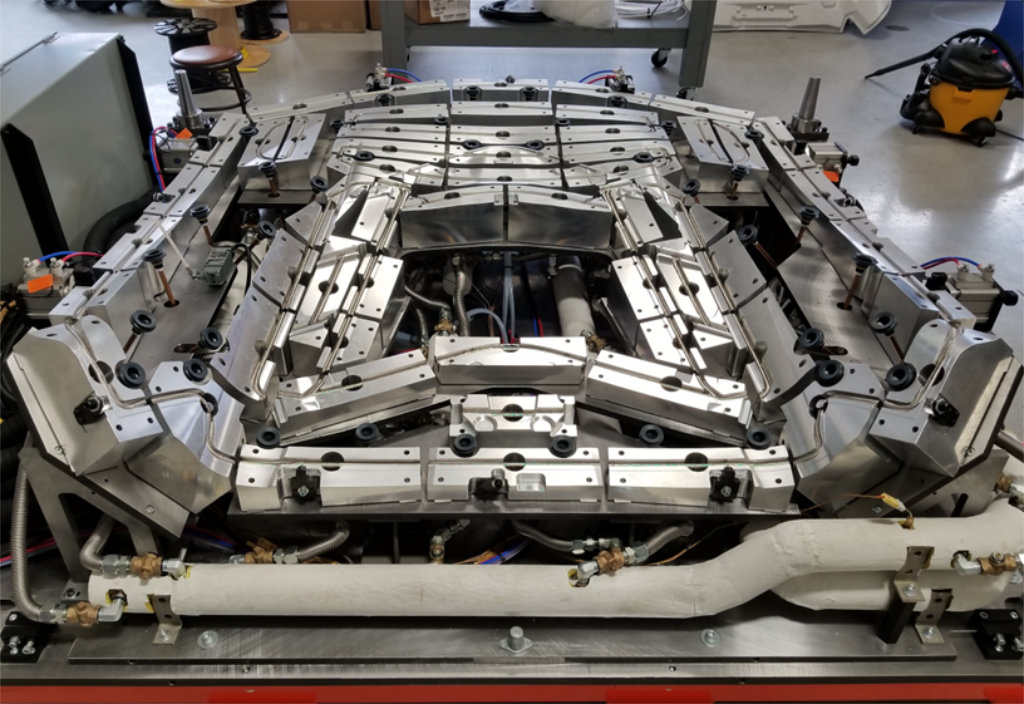

ELECTRIC CARTRIDGE HEAT METHOD

- Reasons for external heat

- Accelerate chemical reaction

- Improve adhesive characteristics

- Application of heat

- Controlled temp. – 200-375F – 93-190C

- Confined positioning – to the adhesive area

- Individual heat block control with thermocouple feedback

- Heat remains constant during release of assembly

- Improved consistency of part dimensions

- Accelerate chemical reaction

- Improve adhesive characteristics

- Easier to understand/maintain

- Little day-to-day variation